Boiler Water Treatment for Feedlots

Save More With Better Feedlot Water Treatment

For feedlots, water is an important asset, and is something that shouldn’t be overlooked. Boiler water treatment for feedlots is important – low quality treatment can lead to a loss of efficiency and a steady degradation of costly machinery. Regular boiler treatment can save your business money in the long run by reducing water and fuel usage, preventing premature equipment failure, and reducing scale buildup inside the boiler for increased heat transfer.

How Boiler Water Treatment Saves You Money

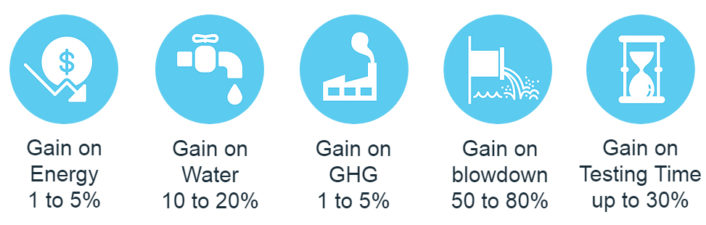

Switching to Purified Tannin technology can improve the efficiency of your feedlot boilers and save you money in the long run

Boilers need water treatment in order to function at their maximum efficiency. Leaving boilers untreated or poorly-treated can lead to problems down the line like corroded pipes or scale deposits that reduce heat transfer and increase the amount spent on fuel and water each year. Proper water treatment on the other hand can keep boilers clean, reducing scale and protecting from corrosion while also improving boiler efficiency. Purified tannin technology allows boilers to run above ASME guidelines for cycle concentration. On top of that, they’re easier to test and don’t require tedious titrations.

Reduce Impurities to Save Big on Fuel

Did you know that a layer of scale as thin as an eggshell can increase fuel usage by up to 10%? Fuel is a huge expense for boiler-heavy operations, and scale buildup can lead to tens of thousands of dollars lost each year, or more.

Our products, like purified tannins, can not only protect against scale buildup, but can actually remove pre-existing scale over time. Heat transfer is critically important to the efficiency of boilers and even a small amount of scale can have a huge, negative impact. To make sure you aren’t overspending on fuel, water treatment by professionals is necessary.

Increase Equipment Lifespan

Boilers aren’t cheap, and they don’t last forever. But that doesn’t mean that they can’t last a long time. To maximize the working lifespan of high-temperature water applications, water treatment is a must. A lot of capital goes towards the purchase of industrial boilers and premature equipment failure can set you back more than you realize. Corrosion and the slow degradation of metal over time can take years off your boiler. Treatment options like purified tannins can protect against the wear and tear of water in boilers to keep them healthy and efficient for a long time.

Questions? Contact Our Experts for More Information!

Keeping your boilers clean and running smoothly can increase the lifespan of your equipment and help keep your business in the green. If you are interested in learning more about purified tannin or our other water treatment solutions, or have questions about other types of water treatment, click the button below. One of us here at FCT Water would love to talk with you and answer any questions you might have.