Boiler Water Treatment for General Manufacturing

Protect and Save With Boiler Water Treatment

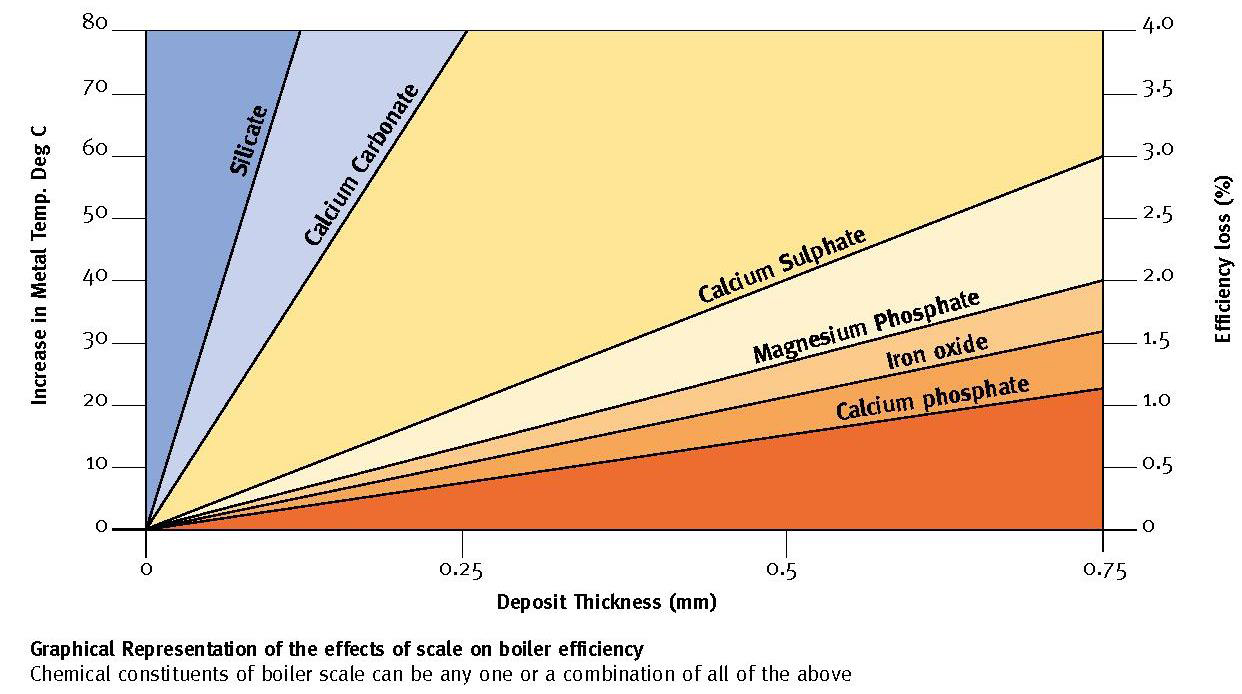

Boilers are frequently used in many different manufacturing processes. For this reason, boiler water treatment for general manufacturing is important. Water is already susceptible to a variety of issues, and high-temperature environments like boilers can be especially at-risk of those issues. What’s more, certain issues like scale buildup on heat-transfer surfaces can reduce the overall efficiency of a boiler significantly, leading to increased costs for water and fuel-usage. To save money and protect your boiler, contact a water treatment professional to find out what options you have.

Reduced Costs, Fewer Problems

Industrial boilers need water treatment in order to function at maximum efficiency. Untreated or poorly-treated boiler water can reduce efficiency and even damage the equipment over time by leading to problems such as corrosion and pitting, or scale formation. Good boiler water treatment can prevent or remediate these problems through a variety of means including pre-treatment and chemical treatment options.

Depending on the application, boiler type, and make-up water requirements, water must be treated in different ways, often including several steps to achieve optimal water. Common water-related issues include corrosion, scaling, fouling, and biological growth. To defend against these and ensure ideal water, a treatment expert may implement a plan that includes pre-treatment solutions like filtration or reverse osmosis, as well as use products like purified tannins or filming amines to achieve the correct water quality.

Find Out More About Boiler Water Treatment

Proper water treatment can make a huge difference in water-based applications like boilers, and can end up saving you a significant amount of money over time. To learn more about boiler water treatment or other water solutions offered by FCT Water, click the button below and we’ll get back to you right away.